The Mustang Cat Rental Store helps you solve your equipment and construction challenges through our vast equipment offerings, quick response times, and proximity – having convenient rental locations throughout Southeast Texas. If you need assistance with your equipment rental, please do not hesitate to get in touch with us, we are happy to help.

Rental Equipment

Optimize Your Job Site

With its headquarters in Houston, Texas, Mustang Cat is a privately-held Cat dealership which has been in the forefront of construction and power systems equipment for 70 years. Mustang Cat is currently led by, Owner, Brad Tucker. Brad was preceded by great company leaders such as Otis Massey, Frank L. Tucker, and Earl C. Calkins, who paved the way with their foresight and leadership, making Mustang Cat what it is today – a customer solutions organization. With its headquarters in Houston, Texas, Mustang Cat is a privately-held Cat dealership which has been in the forefront of construction and power systems equipment for 70 years. Mustang Cat is currently led by, Owner, Brad Tucker. Brad was preceded by great company leaders such as Otis Massey, Frank L. Tucker, and Earl C. Calkins, who paved the way with their foresight and leadership, making Mustang Cat what it is today – a customer solutions organization.Mustang Cat

About Us

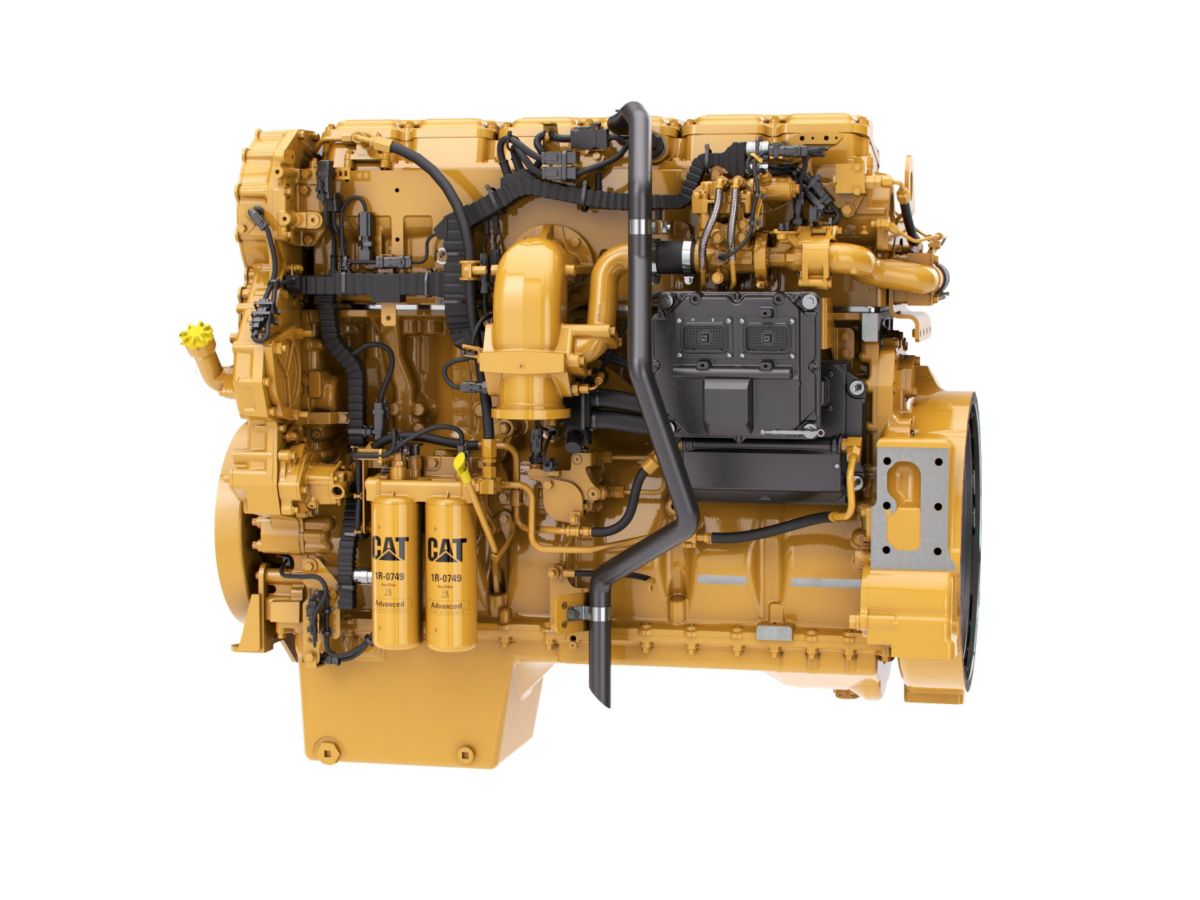

Our parts and service departments are ready to work when you are. Whether you need to order parts online, hydraulic rebuilds, or field service, Mustang Cat can help you with all your parts and service needs.Parts & Service

Keep Your Operation Running Smoothly

“”Good place to rent quality heavy equipment machinery!”” “Great service, they always make things simple and fast. Very much appreciated and recommend.” “Customer service is always exceptional, parts department are quick and always willing to go the extra mile finding the right part.” “Friendly service with knowledgeable employees.”Testimonials

Hear from our Happy Customers

Clark O.

Houston, TX

Krystal C.

Sugarland, TX

John D

Cypress, TX

Mitch S.

Houston, TX

Mustang’s equipment has played a vital role in building landmarks such as the Houston Astrodome, Beltway 8, and the downtown skyline. Mustang Cat caters to construction professionals in Houston and surrounding areas like Beaumont, Lufkin, and Bryan. We give our clients access to durable machines that perform in diverse terrains for repeat success.Our Locations

Find a Mustang Cat near you

If you need equipment advice or just need additional information, we want to hear from you. Questions? We’re here to help:Contact Us

Get in Touch With Us