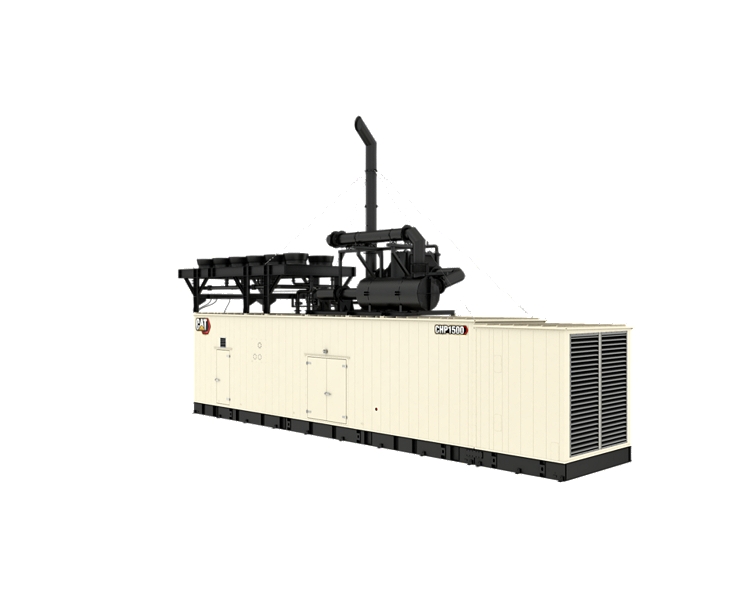

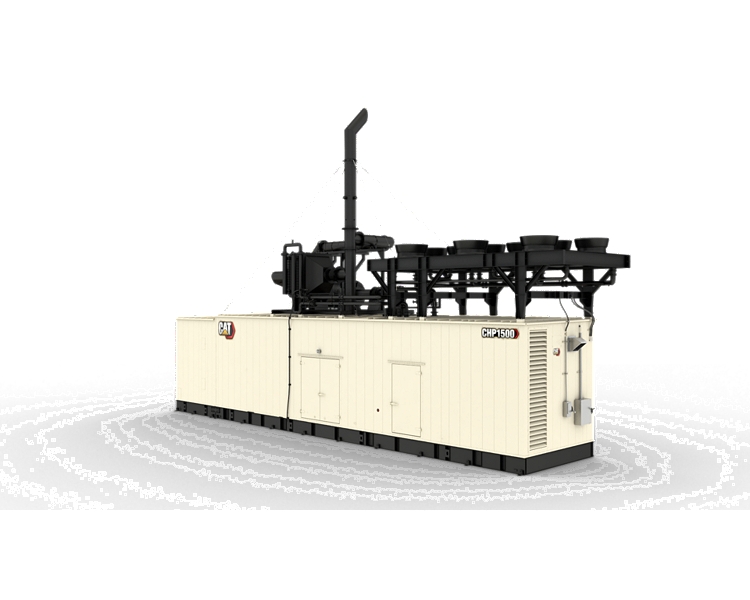

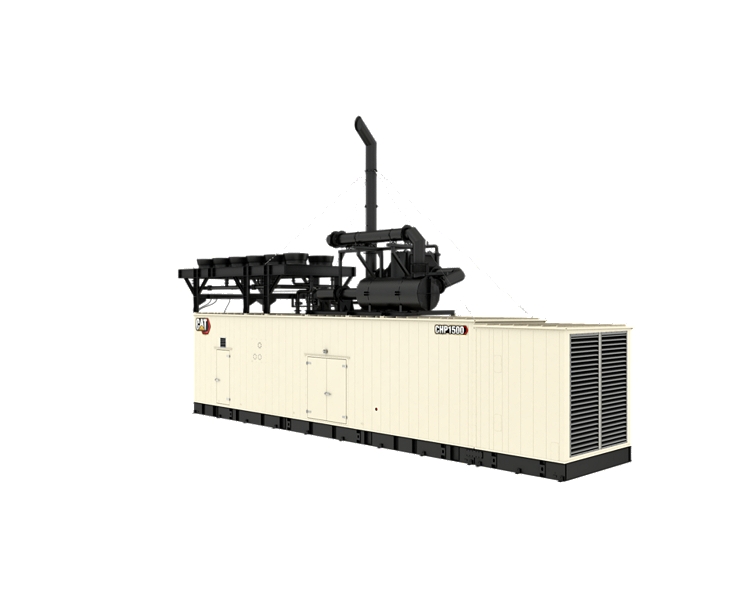

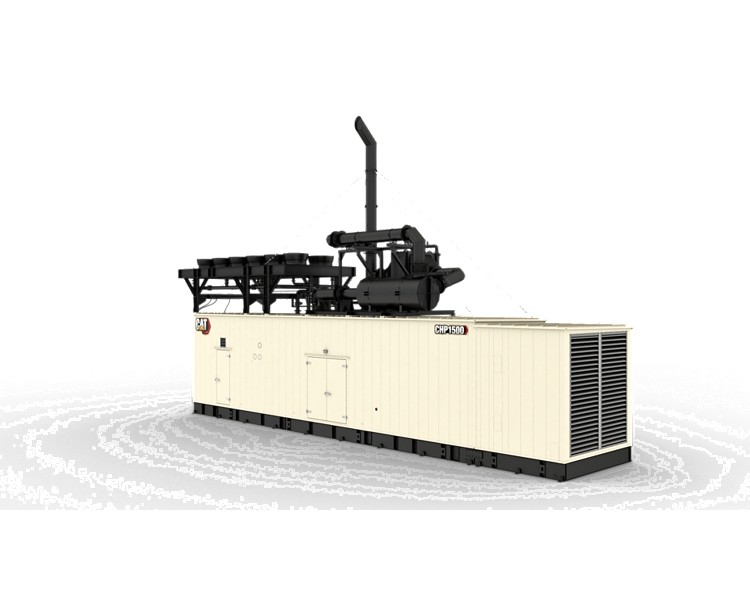

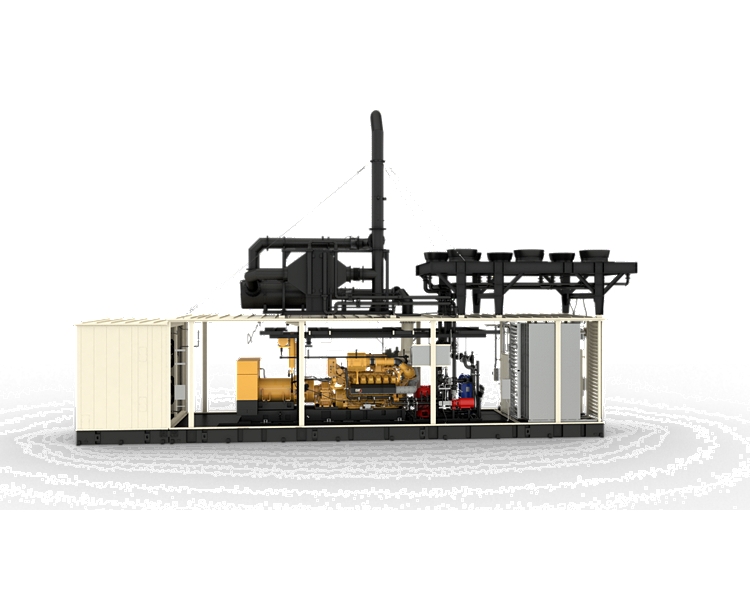

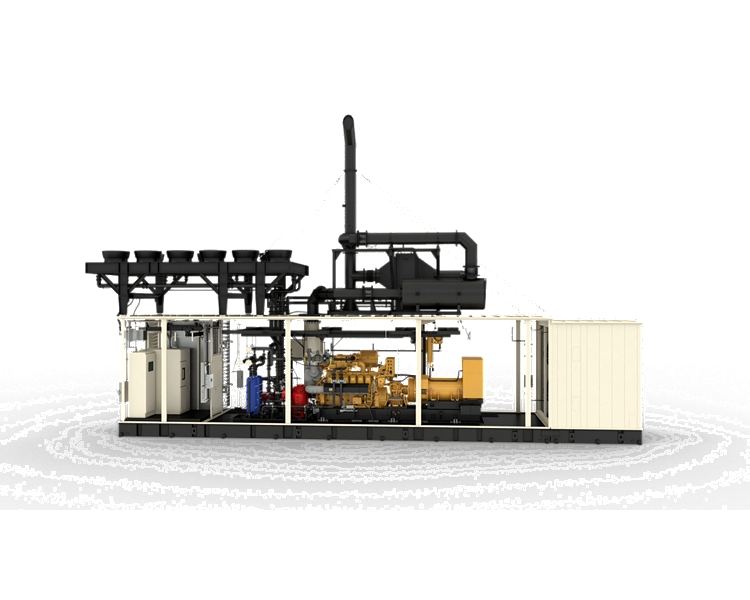

Cat G3512H Combined Heat and Power (CHP) Solution

G3512H Combined Heat and Power (CHP) Solution Gas Generator

Generator Set Specifications

Continuous Rating

Fuel Type

Maximum Electrical Efficiency

Frequency

RPM

Frequency

Engine Specifications

Engine Model

Displacement

Aspiration

Bore

Stroke

Fuel System

Governor Type

Compression Ratio

Generator Set Dimensions

Length

Width

Height

Dry Weight - Genset

Weight

Standard Equipment:

-

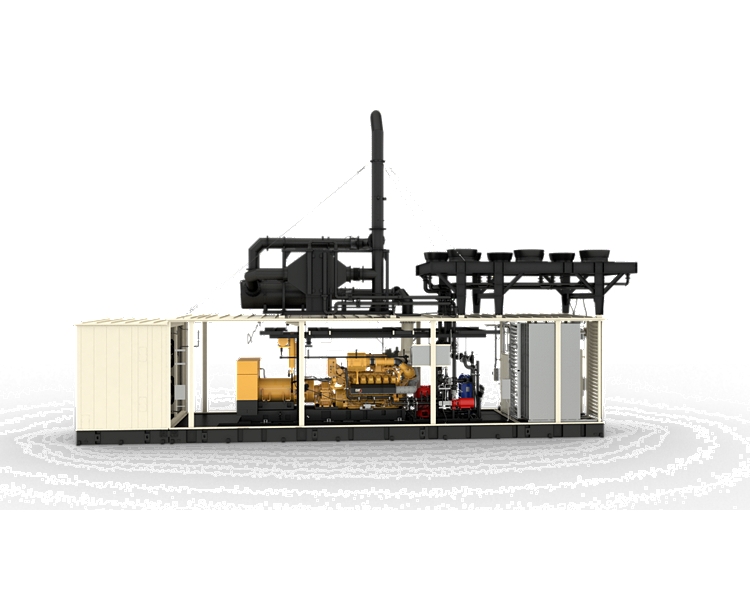

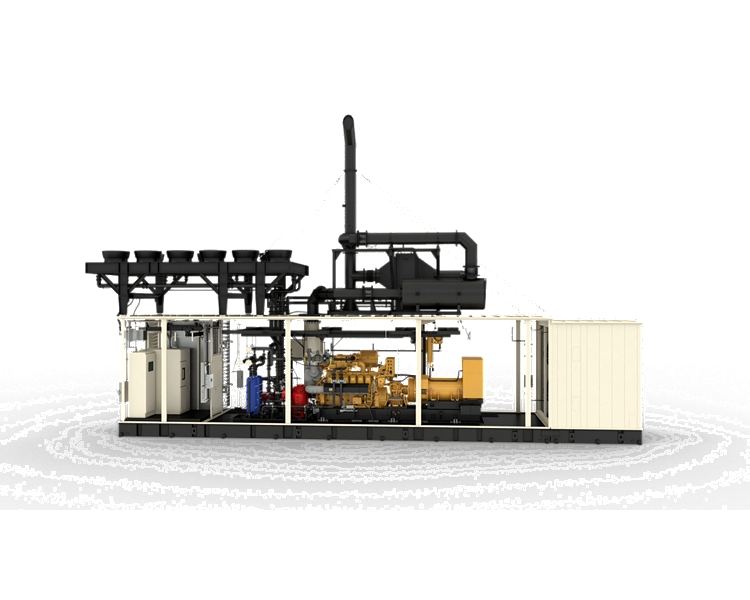

- Engine

-

- G3512H, V12, 4-stroke-cycle, gas engine. Operates on 31.5 to 47.2 MJ/NM3 dry pipeline natural gas. Turbocharged Separate Circuit Aftercooled.

-

- Air Inlet

-

- Package Mounted Air Cleaner with service indicator

-

- Control Panel

-

- On Package EMCP 4.3 Control Panel System Offers engine and generator monitoringand protection, voltage regulation with Cat IVRimproves transient response performance. Controls provide auto paralleling AGC-4 controller, load sharing, VFDcontrol, and primary generator protection for greaterversatility, package utilization and monitoring.

-

- Cooling

-

- ANSI/DN customer flange connections for JW inlet and outlet

- Engine driven water pumps for jacket water and aftercooler

- Jacket water and SCAC thermostats

- Standard cooling provides 40⁰C (104⁰F) ambient capability with 500mg/Nm3 NOx at 100% Continuous rating before derate, @ 500m

-

- Containerized Module

-

- NSPS Factory Compilant, UL2200 Compilant and CSA / TSSA Sound attenuated 75 dB(A) @ 7 m (23 ft) Sound attenuated air intake louvers and lockable personnel doors with panic release LH and RH engine service doors integrated intocontainer side walls 3” ANSI flange customer fuel connection

-

- Generator Controls And Protection

-

- Integrated crankcase ventilation system (CCV)and gas fuel train NFPA37 & CSAB149.3 with external fuel connections package utilization and monitoring.

-

- Modes Of Operation

-

- Provides for single unit stand-alone operation,island mode paralleling and load sharing withother power modules, and single unit-to-utilitymode paralleling for base load control

-

- General

-

- Fire detection system

-

- Lube Oil Make-up System

-

- Integrated enclousre holding tanks: Oil makeup tank (50 gallon), Waste oil tank (300 gal / 2 oil changes), Fresh oil tank (500 gal / 2 oil changes + makeup) and oil level regulator. Low level annunciation

-

- Circuit Breaker

-

- 5000A 3-Pole IEC Rated Circuit Breakers

- LSI Long-Time, Short-Time, Instantaneous Annunciator

- Rear-mounted

-

- Exhaust

-

- Externally mounted exhaust system (muffler and heat exchanger)

- Dry exhaust manifolds, insulated and shielded

- Center section cooled turbocharger with Cat flanged outlet

- Individual exhaust port and turbocharger outlet wired to Integrated Tmeperature Sensing Module (ITSM) with GECM providing alarms and shutdowns

-

- Fuel System

-

- Electronic fuel metering valve

- Throttle plate, 24V DC actuator, controlled by GECM

-

- Fuel System

-

- Fuel system is sized for 31.5 to 47.2 MJ/NM3 dry pipeline natural gas with pressure of 10.2 to 34.5KPa to the engine fuel control valve

-

- Ignition System

-

- Individual Cylinder Detonation Sensitive Timing (DST)

- Electronic Ignition System (controlled by ADEM A4)

-

- Generator

-

- Double bearing SR5 1866 frame, brushless, form wound, 12-lead design, permanent magnet excited, three-phase, with Cat IVR, Class H insulation operating at Class F temperature. Stator and Bearing temperature monitoring and anti-condensation space heaters.

- SR4B

- Caterpillar's Digital Voltage Regulator (CDVR) with 3-phase sensing and KVAR/PF control

- Busbar connections

- Paint- Caterpillar Yellow except rails gloss black

- Winding temperature detectors

- Parts book

- RH Service

- Anti-condensation space heater

- SR5

- Operation and maintenance manuals

- Crankshaft Vibration Damper and Guard

- Reactive droop

-

- Govrerning System

-

- ADEM A4 4-20mA (0-5VV) Speed Input

Optional Equipment:

-

- Air Inlet

-

- Mounting Brackets and Piping

- Air cleaner with precleaner

-

- Circuit Breaker

-

- MP- Frame 6 Pole Bottom Cable Entry

- Frame Mounting

- 4000/5000A Neutral Current Transformer Automatic Selection

- No UV trip or package mounted CB Wiring

-

- Control Panel

-

- Discrete I/O Module, 12 Digital Inputs, 8 'Form C' Relay

- Local PC Monitorring

- 16 Point/32 Light Annunciator, Shipped Loose

- Remote PC Monitorring

- Synchronizing module

- Remote annuciator

- Local alarm module

- Engine failure relay

- Cat Connect: Ehternet, Satellite, Cell Telematics

- Remote Communications Module (PL1000T, PL1000E)

-

- Cooling

-

- Inlet/Outlet connections

- Coolant level drain line with valves, fan with guard

-

- Exhaust

-

- Muffler and spark-arresting muffler with companion flanges

- Elbow

- Flange

- Flexible Fitting

- Exhaust Expander

- Oxidation catalyst

-

- Fuel System

-

- Gas pressure regulator

- Gas Knockdown Regulator

- Fuel filter

- Gas shutoff valve 24V, ETR (Energized-To-Run)

-

- Generator

-

- European bus bar

- Cable access box

- Manual voltage control

- Medium and high voltage generators and attachment

- Low voltage extension box

- Bearing temperature detectors

- Generator air filter

-

- General

-

- Special paint order

- Tool set

- Digital diagnostic tool

- US AID Emblem

- Cold-weather bundle including enclosure heaters and ventilation recirculation

- Fire suppression system

- Interior DC lighting system with automatic shutoff timer

-

- Starting/charging

-

- 24V starting motors

- Jacket water heater

- Battery with cables and rack (shipped loose)

- 60A, 24V charging alternator (requires engine driven pumps)

Contact Us

Get A Quote

Thank you for your interest in Mustang Cat. We are here to help you in any way that we can. If you have a question, need equipment advice or just need additional information, we want to hear from you. You can email, phone or fill out the form below and we will be happy to connect with you.