Power Rating

Power Range

Minimum Rating

Maximum Rating

Generator Set Specifications

Frequency

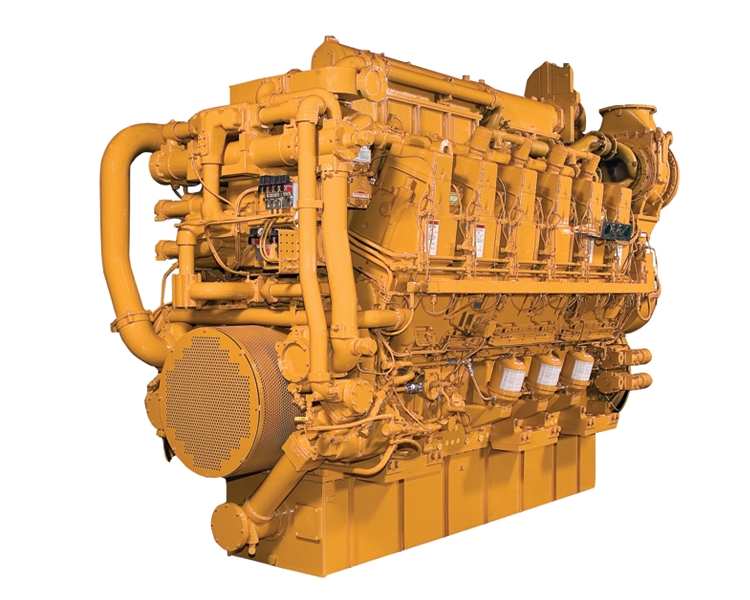

Engine Specifications

Emissions

Aspiration

Bore

Stroke

Configuration

Dimensions & Weights

Maximum Width

Minimum Height

Minimum Dry Weight

Maximum Height

Minimum Width

Minimum Length

Maximum Length

Maximum Dry Weight

Standard Equipment:

-

- Air Inlet System

-

- R INLET SYSTEM Aftercooler, fresh water, corrosion resistant coated (air side) Air inlet shutoff Breather, crankcase, top-mounted Turbocharger, rear-mounted, engine oil lubricated

-

- Control System

-

- Single Caterpillar A-III Electronic Engine Control Modules with Electronic Unit Injector Fuel System Rigid Wiring Harness (10 amp 24volt power required to drive Electronic Engine Control Modules)

-

- Cooling System

-

- Engine coolant water drains

-

- Exhaust System

-

- Dry, gas tight, exhaust manifold

-

- Fuel System

-

- Distillate fuel (requires viscosity ranging from 1.4 cSt to 20 cSt at 38 degrees C) Fuel transfer pump (mounted on left hand side) Duplex fuel filters Electronically Controlled Unit Injectors

-

- Lube System

-

- Centrifugal oil filters with single shutoff. Service side engine mounted on cylinder block inspection covers. Includes installed oil lines and single shutoff valve. Filters centrifuge bypass oil from the main lubricating oil pump. Can be serviced with the engine running. Oil filler and dipstick Valve, oil pressure regulating Valves, crankcase explosion relief

-

- General

-

- Paint, Caterpillar yellow Pumps, gear driven: fuel, oil, jacket water, aftercooler/oil cooler water

-

- Svce Tools/ship Prot/factory Support

-

- Service literature. Included standard with each engine are two (2) complete sets of service literature listed below: 1. Custom parts book CD (serial number specific) 2. Service manual, which includes: Operation & Maintenance, Specifications, Systems Operation, Testing and Adjusting, Disassembly and Assembly manual. Available in paper media and English language only. 3. Technical manual (parts/service information for special equipment). Available in paper media in English language only. NOTE: Custom parts book CD and service manual can be re-ordered through the normal Caterpillar literature ordering system. The technical manual can only be re-ordered through the Project Services at the Caterpillar Lafayette Engine Center facility.

Optional Equipment:

-

- Air Inlet System

-

- Air Cleaners

-

- Cooling System

-

- Jacket Water Heaters

- Heat Recovery System

- Heat Recovery Thermostats

- Cooling System Connection Groups

- De-Aerator

-

- Control System

-

- Load Sharing module

- Direct Rack Module

-

- Exhaust System

-

- Outlet Expander

- Flexible Exhaust Fittings

- Weld Flange - Optional

-

- Fuel System

-

- Fuel Priming Pump

- Duplex Primary Fuel Strainer

- Fuel System Connections

-

- Lube System

-

- Oil Pan Drain Valve

- Prelubrication Connections

- Lube Oil Heater

-

- Mounting System

-

- Vibration Isolators

-

- Marine Society Requirements

-

- Spray shielding

-

- Protection System

-

- PLC Monitoring System Options

- ECP Relay System Options

- ECP Mechanical Gauge Instrument Panel

- Turbocharger Speed Sensor

- Cylinder Pressure Relief Valve

- Oil Mist Detector

- Protection System Components

- Magnetic Pickup

-

- Spare Part Kits

-

- Intake and Air System

- Basic Engine

- Cylinder Head

- Fuel System

- Cooling System

- Instrumentation

- Cylinder Valve Kits

-

- Engine Testing

-

- Basic System Testing

- Special Witness Test

- Torsional Vibration Analysis

-

- Service Tools / Shipping Protection / Factory Support

-

- Commissioning

- Service Tools

- Factory Packaging

- Shipping Protection-Shrink Wrap or Tarp

- Shipping Protection-Export Boxing

- AID Emblem

- Storage Preservation

Contact Us

Get A Quote

Thank you for your interest in Mustang Cat. We are here to help you in any way that we can. If you have a question, need equipment advice or just need additional information, we want to hear from you. You can email, phone or fill out the form below and we will be happy to connect with you.