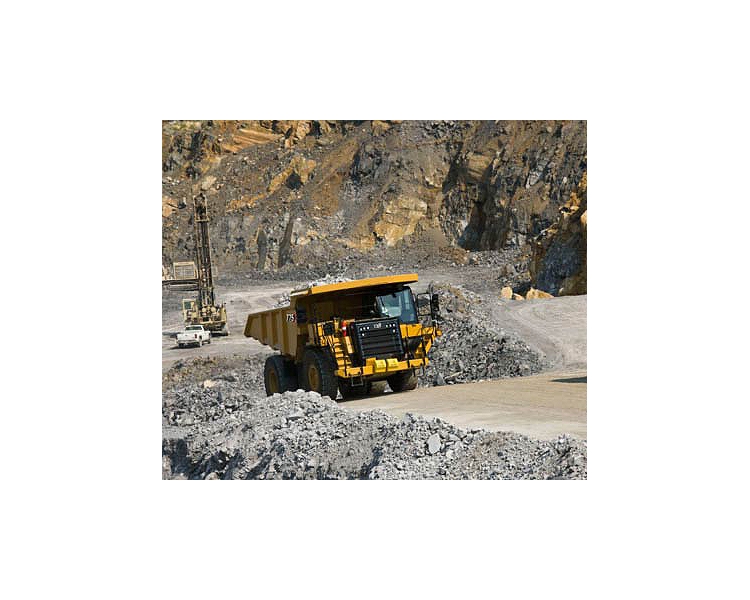

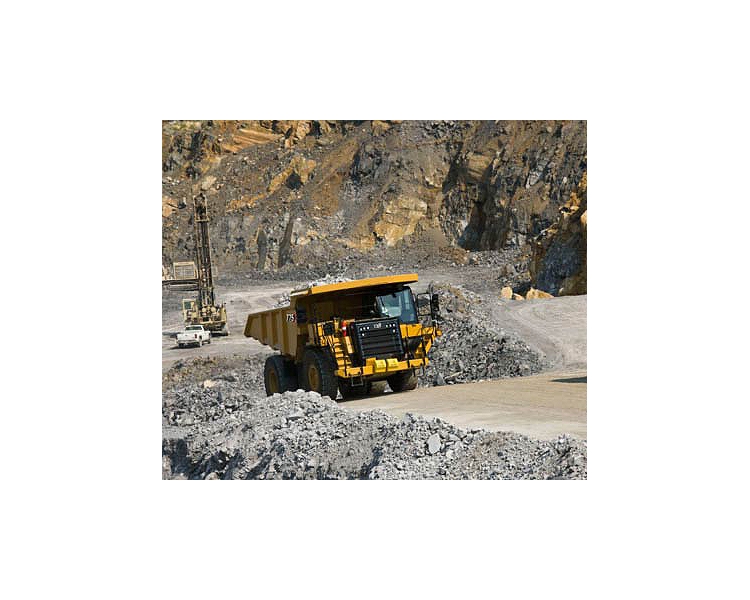

775 Off-Highway Truck

Having a solid track record in the quarry and aggregates industry, Cat’s 775 has been designed and manufactured using the latest quality control technologies—both virtually and hands-on—to ensure your Off-Highway Truck is ready to do work. Built with a Cat C27 diesel engine, the 775 has improved fuel efficiency and delivers an additional 5% horsepower. Our 775 is a great pass match for the Cat 988K or 990K Wheel Loader, too. By having the Cat Off-Highway Trucks in your haul fleets, you can be more productive, spend less time on maintenance, and support the environment with new levels of eco performance. Which ultimately allows you to make a positive impact within your business and community every day.

Operating Specifications

Nominal Payload Class (100%)

Top Speed - Loaded

Maximum Working Payload (110%)

Target Payload (100%)

Maximum Allowable Payload (120%)*

Note (2)

Note (1)

Body Capacity - SAE 2:1

Engine

Engine Model

Rated Engine Speed

Gross Power - SAE J1995:2014

Net Power - SAE J1349:2011

Net Power - 80/1269/EEC

Net Power - ISO 9249

Bore

Stroke

Displacement

Engine Power - ISO 14396

Note (2)

Net Torque

Peak Torque - Speed

Note (1)

Note (3)

Emissions

Capacity - Dual Slope - 100% Fill Factor

Struck

Heaped (SAE 2:1)*

Note (1)

Note (2)

Capacity - Flat Floor - 100% Fill Factor

Struck

Heaped (SAE 2:1)*

Note (1)

Note (2)

Weight Distributions - Approximate

Front Axle - Empty

Front Axle - Loaded

Rear Axle - Empty

Rear Axle - Loaded

Transmission

Forward - 1

Forward - 2

Forward - 3

Forward - 4

Forward - 5

Forward - 6

Forward - 7

Reverse

Note

Final Drives

Differential Ratio

Planetary Ratio

Total Reduction Ratio

Brakes

Brake Surface - Front

Brake Surface - Rear

Brake Standards

Service Refill Capacities

Fuel Tank

Cooling System

Differential - Final Drives

Steering Tank

Steering System - Including Tank

Brake Hoist System

Torque Converter - Transmission System - LRC

Crankcase

Brake/Hoist Hydraulic Tank

Torque Converter - Transmission System - HRC

Body Hoists

Pump Flow - High Idle

Relief Valve Setting - Raise

Relief Valve Setting - Lower

Body Raise Time - High Idle

Body Lower Time - Float

Body Power Down - High Idle

Weights - Approximate

Maximum Gross Vehicle Weight

Suspension

Empty Loaded Cylinder Stroke Front

Rear Axle - Oscillation

Empty Loaded Cylinder Stroke Rear

Tires

Note (2)

Note (1)

Standard Tire

ROPS

FOPS Standards

ROPS Standards

Sound

Sound Standards (1)

Sound Standards (2)

Sound Standards (3)

Steering

Turning Diameter - Front

Steering Standards

Steer Angle

Turning Circle - Clearance Diameter

Sustainability

Recyclability

Standard Equipment:

-

- Note

-

- Standard and optional equipment may vary. Consult your Cat dealer for details.

-

- Power Train

-

- Cat C27 Tier 4/Stage V compliant diesel engine:

– Air cleaner with precleaner (2)

– Air-To-Air Aftercooler (ATAAC)

– Electric start

– Engine idle shutdown

– Ether starting aid

– Exhaust muffler

– NGMR radiator - For Tier 4 regions only (U.S./Canada):

– Aftertreatment system- NOx Reduction System (NRS)

- Diesel Oxidation Catalyst (DOC)

– Demand fan

– MEUI-C fuel system - Braking system:

– Extended Life Brakes

– Automatic Retarder Control (ARC)

– Manual retarder (utilizes rear oil-cooled, multiple disc brakes)

– Brake release motor (towing)

– Dry disc brakes (front)

– Front brake disconnect switch (front)

– Oil-cooled multiple disc brakes (rear)

– Brake wear indicator (rear)

– Parking brake

– Secondary brake

– Service brake - Transmission:

– 7-speed automatic powershift with:- Electronic Clutch Pressure Control (ECPC)

- Advanced Productivity Electronic Control Strategy (APECS)

– Automatic neutral idle

– Autostall

– Second gear start

- Cat C27 Tier 4/Stage V compliant diesel engine:

-

- Suspension Systems

-

- Suspension, front and rear

-

- Electrical

-

- Alarm backup

- Alternator, 120 Amp

- Autolube power supply ready

- Batteries, maintenance-free, 12V (2), 1,400 CCA combined

- Electrical system, 25 Amp, 24V to 12V converter

- Lighting system:

– Backup light (halogen)

– Directional signals/hazard warning (front and rear LED)

– Engine compartment light

– Headlights, (halogen) with dimmer

– Operator access courtesy lights

– Side profile lights

– Stop/tail lights (LED) - Service center containing:

– Battery jump start

– Breakers with spare fuses

– Lockout switch

– Ports, ET, and VIMS

– Service lockout switch (power without engine start)

-

- Technology Products

-

- Economy Modes, standard and adaptive

- Product Link, cellular or satellite

- Traction Control System (TCS)

- Truck Production Management System

- Vital Information Management System (VIMS)

-

- Operator Environment

-

- Advisor display:

– Air cleaner service indicator

– Fluid level monitoring

– Fuel level monitoring

– Display languages (market based) - Air conditioning/heat

- Automatic temperature control

- Ashtray and cigarette lighter

- Coat hook

- Cup holders (4)

- Diagnostic connection port, 24V

- Entertainment radio ready:

– 5 amp converter

– Speakers

– Antenna

– Wiring harness - Foot rest

- Gauges/indicators:

– Brake oil temperature gauge

– Coolant temperature gauge

– Engine overspeed indicator

– Fuel level

– Hour meter

– Speedometer with odometer

– Tachometer

– Transmission gear indicator - Hoist lever

- Horn

- Light – courtesy

- Light – dome

- Mirrors, non-heated

- Power port, 24V and 12V (2)

- Rollover Protection (ROPS)/Falling Object Protection (FOPS)

- Seat, Cat Comfort Series III:

– Full air suspension

– Retractable 3-point seat belt with shoulder harness - Seat, training with lap belt

- Steering wheel, padded, tilt and telescopic

- Storage compartment

- Sun visor

- Throttle lock

- Window, hinged, right side (emergency exit)

- Window, powered, left side

- Windshield wiper intermittent and washer

- Advisor display:

-

- Guards

-

- Driveline

- Engine crankcase

- Fan

-

- Fluids

-

- Antifreeze

- Extended life coolant to –34° C (–30° F)

- Grouped ground-level filters

-

- Other Standard Equipment

-

- Body down indicator

- Body safety pin (secures body in up position)

- Center-mounted rims

- Fuel tank, 795 L (210 gal)

- Ground level battery disconnect

- Ground level engine shutdown

- Ground level grease fittings

- Operator Maintenance Manual (OMM)

- Rims 17 × 35

- Rock ejectors

- Secondary steering (electric)

- Tie down eyes

- Tow hooks (front)/tow pin (rear)

- Vandalism protection locks

Optional Equipment:

-

- Note

-

- Standard and optional equipment may vary. Consult your Cat dealer for details.

-

- Optional Equipment

-

- Body heat

- Body liner

- Body sideboards

- Cab precleaner

- Cat Engine Brake

- Clustered grease fittings

- Cold weather packages

- Fluid fill service center

- HID lights

- Mirrors, convex

- Mirrors, heated

- Spare rim

- Visibility package (meets ISO 5006 requirements)

- Wheel chocks

- Work Area Vision System (WAVS)

Contact Us

Get A Quote

Thank you for your interest in Mustang Cat. We are here to help you in any way that we can. If you have a question, need equipment advice or just need additional information, we want to hear from you. You can email, phone or fill out the form below and we will be happy to connect with you.